Isishwankathelo

I-margarine ye-pastry kufuneka ibe yiplastiki kwaye ihlale iqinile. Ukuhamba kobuchwephesha bokuvelisa i-margarine ye-pastry kunokucwangciswa lula yi-tubularchiller (i-tubular scraped surface heat exchanger). Ngexesha lokucubungula ioyile nzulu, ukupholisa kunempembelelo enkulu kwi-crystallization ye-margarine ye-pastry. I-margarine eyahlukeneyo ifuna inkqubo eyahlukileyo kunye nemeko yokufudumala.

I-margarine ye-pastry kufuneka ibe yiplastiki kwaye ihlale iqinile. Ukuhamba kobuchwephesha bokuvelisa i-margarine ye-pastry kunokucwangciswa lula yi-tubularchiller (i-tubular scraped surface heat exchanger). Ngexesha lokucubungula ioyile nzulu, ukupholisa kunempembelelo enkulu kwi-crystallization ye-margarine ye-pastry. I-margarine eyahlukeneyo ifuna inkqubo eyahlukileyo kunye nemeko yokufudumala.

Amagama angundoqo: i-pastry margarine; idramu ebandayo; i-tubular chiller, i-scraped heat exchanger, imveliso ye-margarine.

Ukwaziswa kobuchwephesha kwe-tubular chiller

Nangona iimveliso ze-margarine eziqhekekileyo bezisoloko zisenziwa kangangeminyaka emininzi, abantu bebezama ukufumana eyona ndlela ilungileyo yeemeko zenkqubo, ikakhulu kwi-crystallization yefomyula yemveliso eyahlukeneyo phantsi kweemeko ezahlukeneyo zokucubungula. Ngaphambi kokuba kuqalwe i-scraper heat exchanger, okanye umatshini wokucima ityhubhu, zonke iimveliso ze-margarine zaziveliswa kusetyenziswa oomatshini bokucima iidramu kunye nokuxova. Ngenxa yomatshini wokucima ityhubhu, uneengenelo ezininzi xa kuthelekiswa nezinye iimatshini zokucubungula, ngoko ke ngoku abavelisi be-margarine basebenzisa imveliso yabo ye-margarine ye-pastry eqhekekileyo, eli phepha lithetha ngomatshini wokucubungula ityhubhu yokucima ukuvelisa inkqubo ye-margarine ye-pastry eqhekekileyo ukwenza intshayelelo.

Iimpawu eziphambili zemargarine eqhekekileyo kukunyibilika kwayo kunye nokuqina kwayo. Xa imargarine isongiwe kwaye iqengqeleka ngokuphindaphindiweyo, iileya kufuneka zihlale zingaqhekeki entlameni, ngoko ke ukunyibilika kubalulekile; Uzinzo nalo lubalulekile. Ukuba imargarine ayiqinanga ngokwaneleyo ukuba ithambe okanye i-oyile ingene, kwaye ifunxwe entlameni, umaleko weoyile phakathi kweeleya zentlama uya kuncipha kakhulu.

Ulwakhiwo lomatshini wokucima iidrama ojikelezayo lulula kakhulu, kufuneka uhlengahlengise iiparameter ezimbalwa kwimveliso ukuze kuvele iimveliso zemargarine eziqinileyo. I-margarine ye-pastry eqhekekileyo eveliswa ngumatshini wokucima iidrama inobunkunkqele obuhle, ayilula ukungena kwioyile, kwaye izinzile kakhulu kubushushu obukhulu. Umatshini wokucima iityhubhu kunomatshini wokucima iidrama ekusebenzeni kwawo uye wenza inkqubela phambili enkulu, ebonakala kakhulu kwi:

(1) Kwiimveliso zokucubungula imibhobho evaliweyo, ukuvalwa kakuhle, iimeko zococeko nazo ziya kuphucuka kakhulu;

(2) Ukuphunyezwa kokusebenza koxinzelelo oluphezulu, okubaluleke kakhulu ekuvelisweni kwemargarine eqhotsiweyo;

(3) Ukuguquguquka okuhle, kunokutshintsha isantya, uxinzelelo, amandla okukhenkceza kunye nezinye iimeko zokucubungula.

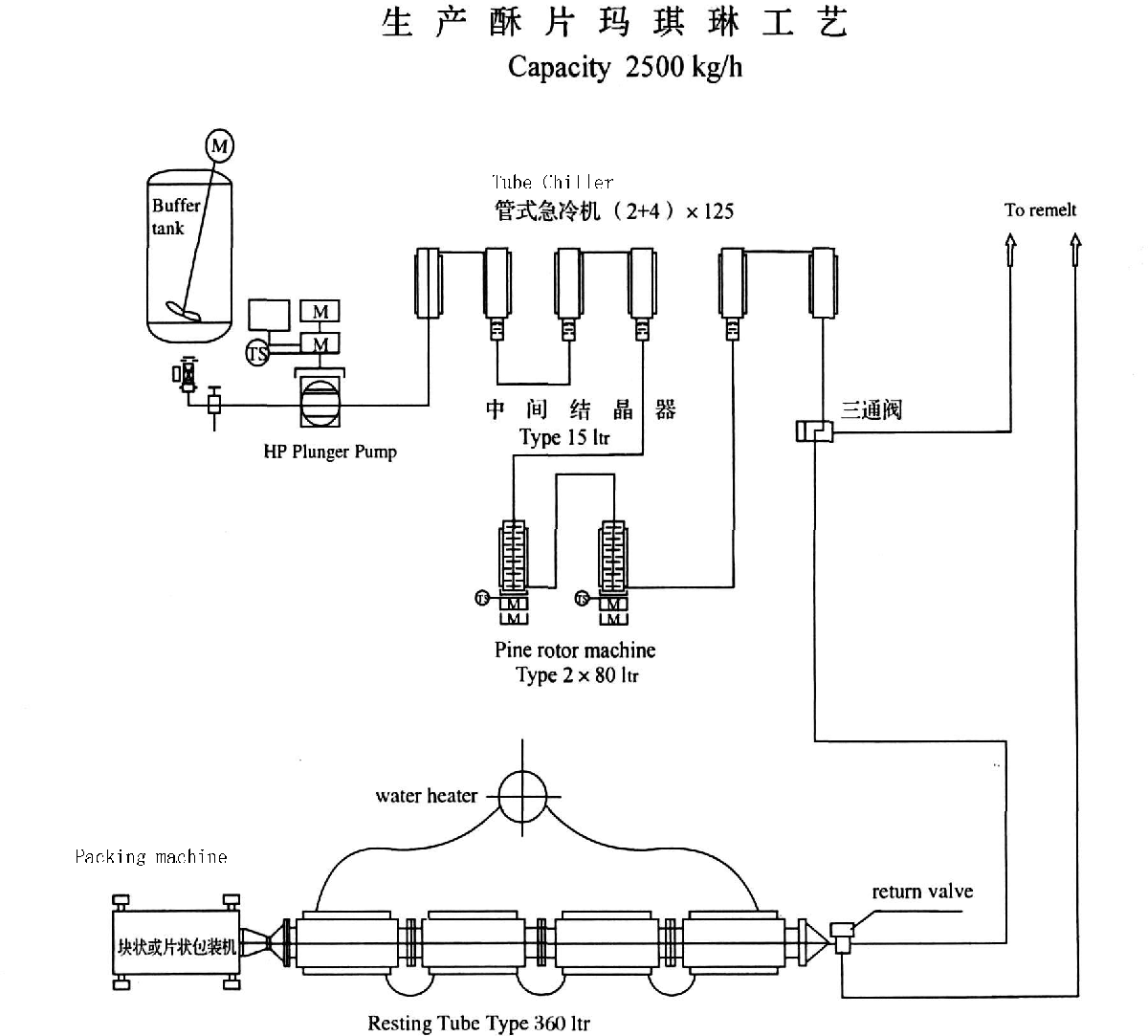

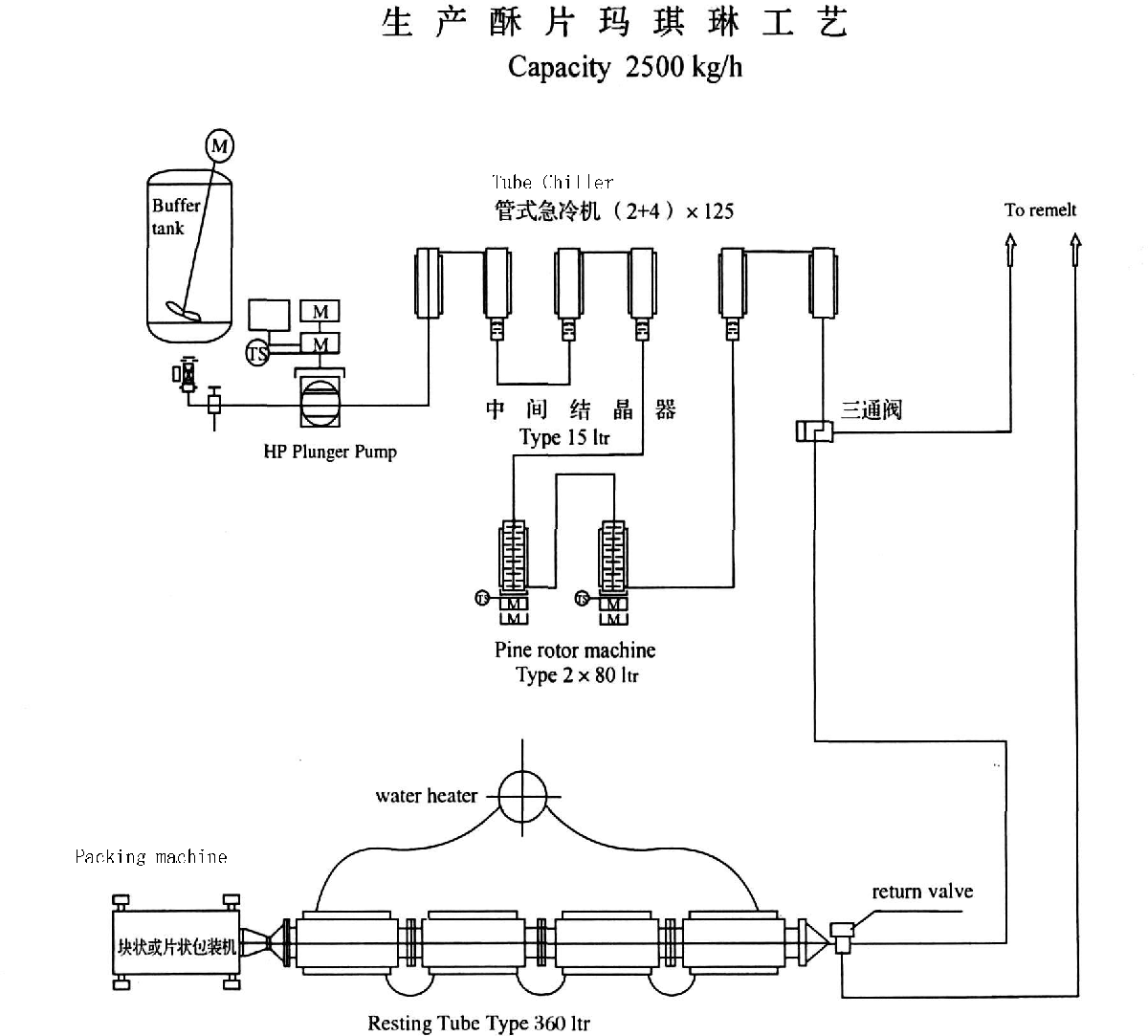

Inkqubo emele ukuveliswa kwemargarine ye-pastry eqhekekileyo ngomatshini wokucima ityhubhu yile ilandelayo:

Impompo ye-plunger enoxinzelelo oluphezulu ※ Isixhobo sokutshintshiselana nobushushu esinoxinzelelo oluphezulu (Iyunithi A) ※ Iseti ye-crystallizer ephakathi ※ Umatshini we-stirring pine rotor (Iyunithi B) ※ Ityhubhu yokuphumla enomthamo omkhulu ※ Ukupakisha izilayi/iibhloko.

Umsebenzi we-crystallizer ephakathi ulingana nowe-kneader yokuxuba. Ifumaneka kumbhobho wokucima umbane womatshini wokucubungula kwaye iqhutywa ukuze ijikelezwe yi-cutter shaft yomatshini wokucubungula.

Kulula ukulungisa ukuhamba kokucubungula imveliso ukuze kuveliswe i-margarine ye-pastry eqhekekileyo ngomatshini wokucima ityhubhu. Injongo yokulungisa inkqubo inokufezekiswa ngokutshintsha indlela yokudibanisa umbhobho wokudibanisa phakathi kweqela lombhobho wokucima (iyunithi A) kunye neyunithi yokuxova (iyunithi B), okulula ukuyisebenzisa. Umzekelo, iyunithi yokuxova yokuxuba (iyunithi B) ingafakwa phakathi kombhobho wokucima weyunithi A, kulandela ukuhamba kwe-A 1 ※A 2 ※B1 ※B2 ※A 3 ※A 4, okanye ukutshintsha ukuya kukuhamba kwe-A 1 ※A 2 ※A 3 ※A 4 ※B1 ※B2. Ngokutshintsha nje inkqubo yokucubungula kunokuphucula umgangatho wemveliso. Kule nkqubo ingentla, inkqubo yokubeka iyunithi B phakathi kombhobho wokucima weyunithi A ifanelekile ngokukodwa kwifomyula yeoyile yemifuno esekelwe kwioyile yesundu, eye yangqinwa amaxesha amaninzi kwimveliso. Kwaye xa izinto eziphambili zemveliso ziinkomo, iziphumo ezingcono zinokufunyanwa ngokubeka iyunithi B emva kweyunithi A.

Umthamo wokuxova umiselwa yindlela equlunqwe ngayo imveliso, umzekelo, umthamo omkhulu wokuxova kufuneka usetyenziswe kwifomyula yeoyile kunye ne-crystallization ecothayo. Kwinkqubo yokuvelisa umbhobho opholileyo ngokukhawuleza, isiphumo sokuxova sisiphumo somthamo weqela eliphakathi kunye nomthamo we-crystallizer kwaye iyunithi yokuxova (B) inika isixa somthamo weyunithi, ngoko ke xa utshintsho kwifomyula yemveliso, kufuneka kulungiswe umthamo wenkqubo yokuxova, nokuba ngumthamo weyunithi ye-B onyukayo okanye onciphileyo, unokwanda okanye unciphe kumthamo ophakathi wokubumba, Oku kunokwenziwa ngokudibanisa nokuthabatha ngaxeshanye, kuguquguquka kakhulu.

Umthamo wokuxova umiselwa yindlela equlunqwe ngayo imveliso, umzekelo, umthamo omkhulu wokuxova kufuneka usetyenziswe kwifomyula yeoyile kunye ne-crystallization ecothayo. Kwinkqubo yokuvelisa umbhobho opholileyo ngokukhawuleza, isiphumo sokuxova sisiphumo somthamo weqela eliphakathi kunye nomthamo we-crystallizer kwaye iyunithi yokuxova (B) inika isixa somthamo weyunithi, ngoko ke xa utshintsho kwifomyula yemveliso, kufuneka kulungiswe umthamo wenkqubo yokuxova, nokuba ngumthamo weyunithi ye-B onyukayo okanye onciphileyo, unokwanda okanye unciphe kumthamo ophakathi wokubumba, Oku kunokwenziwa ngokudibanisa nokuthabatha ngaxeshanye, kuguquguquka kakhulu.

Ixesha lokuthumela: Disemba-30-2021