ITekhnoloji yoMveliso weMargarine

ISISHWANKATHELO SEBHUNGA

Iinkampani zokutya namhlanje zifana namanye amashishini okuvelisa engagxininisi kuphela ekuthembekeni kunye nomgangatho wezixhobo zokulungisa ukutya kodwa nakwiinkonzo ezahlukeneyo ezinokuziswa ngumthengisi wezixhobo zokusebenza. Ngaphandle kwemigca yokucubungula esebenzayo esiyihambisayo, sinokuba ngumlingani ukusuka kwingcamango yokuqala okanye isigaba seprojekthi ukuya kwisigaba sokugqibela sokumisela, singalibali inkonzo ebalulekileyo emva kokuthengisa.

I-Shiputec ineminyaka engaphezu kwama-20 yamava kushishino lokulungisa ukutya kunye nokupakisha.

INTSHAYELELO KWI-TEKNOLOJIYA YETHU

UMBONO NOKUZINIKELA

Icandelo le-Shiputec liyila, livelisa kwaye lithengisa inkqubo yobunjineli kunye nezisombululo ezizenzekelayo kwimveliso yobisi, ukutya, isiselo, elwandle, amayeza kunye nokhathalelo lomntu ngokusebenzisa imisebenzi yayo yehlabathi.

Sizibophelele ekuncedeni abathengi bethu kwihlabathi liphela ukuba baphucule ukusebenza kunye nenzuzo yesityalo sabo sokwenza kunye neenkqubo. Sifezekisa oku ngokunikezela ngoluhlu olubanzi lweemveliso kunye nezisombululo ezivela kumacandelo obunjineli ukuya kuyilwa kwezityalo zenkqubo epheleleyo exhaswa zizicelo eziphambili zehlabathi kunye nobuchule bophuhliso.

Siyaqhubeka ukunceda abathengi bethu ukuba baphucule ukusebenza kunye nenzuzo yeplanti yabo kubo bonke ubomi benkonzo yabo kunye neenkonzo zenkxaso ezilungiselelwe iimfuno zabo ngenkonzo yabathengi elungelelanisiweyo kunye nenethiwekhi yamacandelo asecaleni.

UKUJONGA KUBATHENGI

I-Shiputec iphuhlisa, ivelise kwaye ifakele iintambo zala maxesha, ezisebenzayo nezithembekileyo kushishino lokutya. Ukwenziwa kweemveliso zamafutha akhazimliswe njengemajarini, ibhotolo, ukusasazeka kunye nokunciphisa i-Shiputec ibonelela ngezisombululo eziquka imigca yenkqubo yeemveliso zokutya ezifakwe emulsified njengemayonesi, iisosi kunye nezinxibo.

IMVELISO YEMAGARINE

I-margarine kunye neemveliso ezihambelanayo ziqulethe isigaba samanzi kunye nesigaba samanqatha kwaye ngoko sinokubonakaliswa njengama-emulsions e-water-in-oil (W / O) apho isigaba samanzi sichithwa kakuhle njengamaconsi kwisigaba samafutha esiqhubekayo. Ngokuxhomekeke ekusebenziseni imveliso, ukubunjwa kwesigaba samafutha kunye nenkqubo yokuvelisa ikhethwa ngokufanelekileyo.

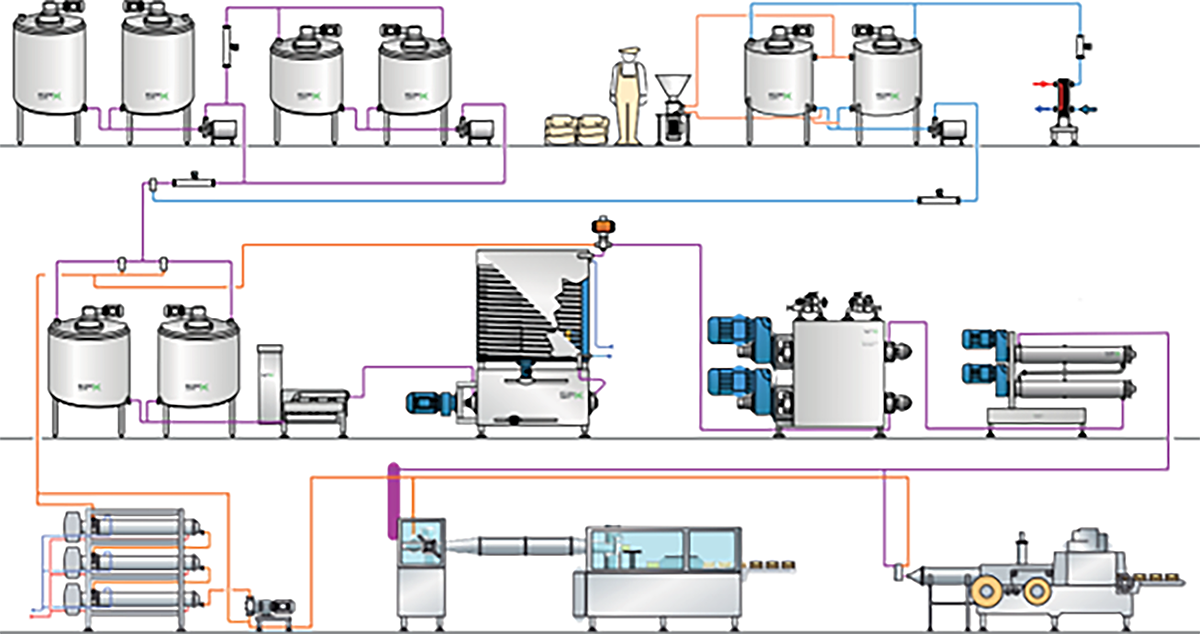

Ngaphandle kwesixhobo sokukhazimlisa iikristale, indawo yokuvelisa imajarini kunye neemveliso ezinxulumene noko iya kubandakanya iitanki ezahlukeneyo zokugcina i-oyile kunye ne-emulsifier, isigaba samanzi kunye nokulungiswa kwe-emulsion; Ubungakanani kunye nenani lamatanki abalwa ngokusekelwe kumthamo weplanti kunye nepotifoliyo yemveliso. Esi sibonelelo sikwabandakanya iyunithi yokuxilisa kunye nesixhobo sokunyibilikisa. Ke ngoko, inkqubo yokuvelisa inokwahlulwa ngokubanzi ibe ziinkqubo ezingaphantsi zilandelayo (nceda ubone umzobo 1):

UKULUNGISWA KWESIGABA SAMANZI KUNYE NESIGABA ESIFUTSHANE (UMZONO 1)

Isigaba samanzi sisoloko silungiswa ngokwebhetshi kwitanki yesigaba samanzi. Amanzi kufuneka abe semgangathweni wokusela. Ukuba amanzi asemgangathweni wokusela akanakuqinisekiswa, amanzi anokufakwa kunyango lwangaphambili kusetyenziswa iUV okanye inkqubo yokucoca.

Ngaphandle kwamanzi, isigaba samanzi sinokubandakanya ityuwa okanye i-brine, iiprotheni zobisi (i-margarine yetafile kunye ne-fat fat spreads), iswekile (i-puff pastry), i-stabilizers (i-fat fat spreads encitshisiweyo kunye ne-low fat), i-preservatives kunye ne-flavour-soluble flavour.

Izithako eziphambili kwisigaba samafutha, umxube wamafutha, udla ngokuquka umxube wamafutha kunye nee-oyile ezahlukeneyo. Ukuze ufezekise i-margarine kunye neempawu ezifunwayo kunye nokusebenza, umlinganiselo wamafutha kunye namafutha kwi-fat blend yisigqibo sokusebenza kwemveliso yokugqibela.

Amafutha ahlukeneyo kunye nee-oyile, nokuba zixutywe ngamafutha okanye i-oyile enye, zigcinwa kwiitanki zokugcina ioyile zibekwe ngaphandle kwendawo yokuvelisa. Ezi zigcinwa kwiqondo lobushushu obuzinzileyo ngaphezu kwendawo yokunyibilika kwamanqatha naphantsi kokuphazamiseka ukuze kuthintelwe ukwahlulwa kwamafutha kunye nokuvumela ukuphatha lula.

Ngaphandle kokudityaniswa kwamafutha, isigaba samafutha sibandakanya izithako ezincinci ezinyibilikayo ezinje nge-emulsifier, i-lecithin, incasa, umbala kunye ne-antioxidants. Ezi zithako ezincinci zichithwa kwi-fat blend phambi kokuba isigaba samanzi songezwe, ngoko ke phambi kwenkqubo ye-emulsification.

UKULUNGISELELA I-EMULION ( ZONE 2 )

I-emulsion ilungiselelwe ngokuhambisa ioli ehlukeneyo kunye neoli okanye i-fat blends kwi-tank ye-emulsion. Ngokuqhelekileyo, amanqatha aphezulu ancibilikayo okanye amanqatha adibeneyo adityaniswa kuqala alandelwa ngamafutha aphantsi ancibilikayo kunye neoli ye-liquid. Ukugqiba ukulungiswa kwesigaba se-fat, i-emulsifier kunye nezinye izithako ezincinci ze-oil-soluble zongezwa kwi-fat blend. Xa zonke izithako zesigaba samanqatha zixutywe ngokufanelekileyo, isigaba samanzi songezwa kwaye i-emulsion idalwe phantsi kokuxuba okunzulu kodwa okulawulwayo.

Iinkqubo ezahlukeneyo zingasetyenziselwa ukulinganisa izithako ezahlukeneyo ze-emulsion apho ezimbini zisebenza ngokulandelelana:

Inkqubo yemitha yokuhamba

Inkqubo yetanki yokulinganisa

Inkqubo ye-emulsification ye-in-line eqhubekayo ayithandwa kakhulu kodwa isisombululo esisetyenziswayo umz. imigca ephezulu yomthamo apho isithuba esilinganiselweyo samatanki e-emulsion akhoyo. Le nkqubo isebenzisa iimpompo ze-dosing kunye neemitha zokuhamba ezininzi ukulawula umlinganiselo wezigaba ezongezelelweyo kwitanki encinci ye-emulsion.

Ezi nkqubo zikhankanywe ngasentla zinokulawulwa ngokupheleleyo ngokuzenzekelayo. Ezinye izityalo ezindala, nangona kunjalo, ziseneenkqubo zokulungiselela i-emulsion ezilawulwa ngesandla kodwa ezi zifuna umsebenzi kwaye azikhuthazwa ukuba zifakwe namhlanje ngenxa yemithetho engqongqo yokulandela umkhondo.

Inkqubo yemitha yokuhamba isekelwe kwi-batch-wise i-emulsion yokulungiselela apho izigaba ezahlukeneyo kunye nezithako zilinganiswa ngeemitha zokuhamba kobunzima xa zidluliswa ukusuka kwiitanki zokulungiselela isigaba ezahlukeneyo kwitanki ye-emulsion. Ukuchaneka kwale nkqubo +/-0.3%. Le nkqubo ibonakala ngokungabi namvakalelo kwiimpembelelo zangaphandle ezifana nokungcangcazela kunye nokungcola.

Inkqubo yetanki yokulinganisa ifana nenkqubo yemitha yokuhamba esekelwe kulungiselelo lwe-emulsion yobulumko. Apha izixa zezithako kunye nezigaba zongezwa ngokuthe ngqo kwitanki ye-emulsion efakwe kwiiseli zomthwalo ezilawula iimali ezongeziweyo kwitanki.

Ngokuqhelekileyo, inkqubo yeetanki ezimbini isetyenziselwa ukulungiselela i-emulsion ukuze ikwazi ukuqhuba umgca we-crystallization ngokuqhubekayo. Itanki nganye isebenza njengento yokulungiselela kunye ne-buffer tank (itanki ye-emulsion), ngoko ke umgca we-crystallization uya kondliwa kwitanki enye ngelixa i-batch entsha iya kulungiswa kwelinye kwaye ngokufanayo. Oku kubizwa ngokuba yi-flip-flop system.

Isisombululo apho i-emulsion ilungiselelwe kwitanki enye kwaye xa ilungile idluliselwe kwi-tank ye-buffer ukusuka apho umgca we-crystallization wondliwe nayo inketho. Le nkqubo ibizwa ngokuba yi premix/buffer system.

I-PASTEURIZATION ( ZONE 3 )

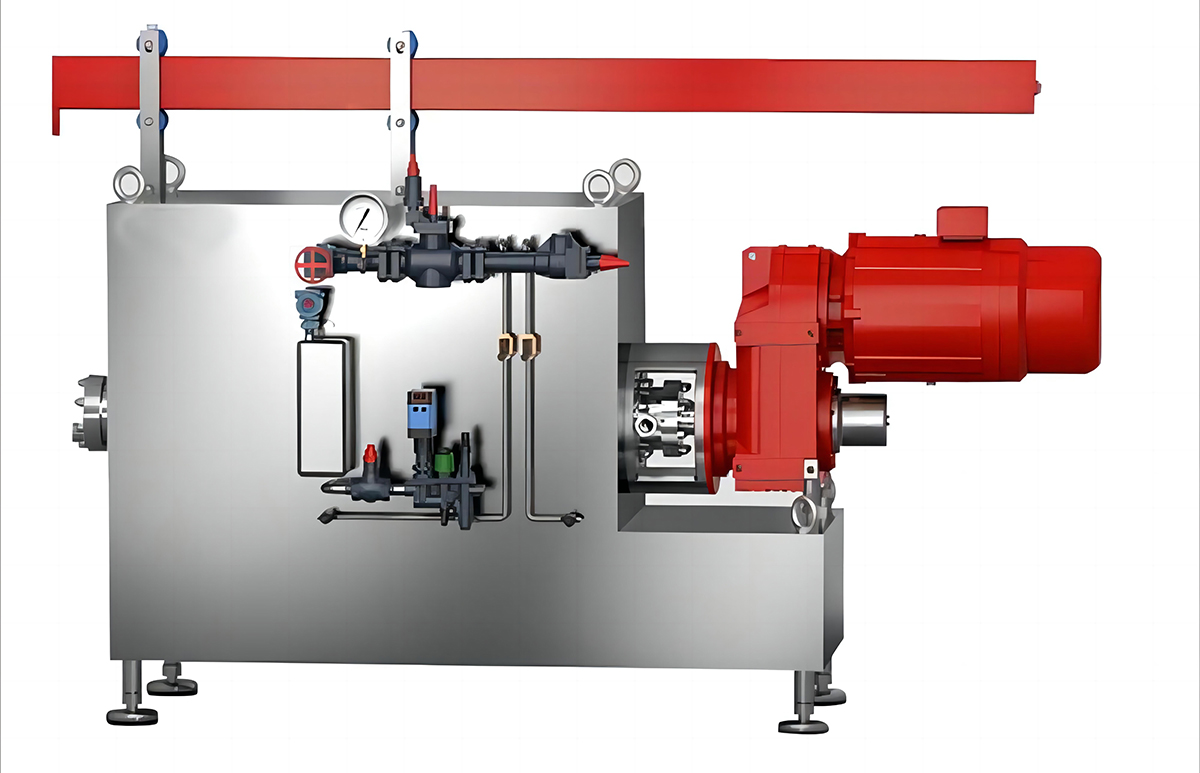

Ukusuka kwitanki ye-buffer i-emulsion iqhele ukumpontshwa ngokuqhubekayo nge-plate exchanger heat (PHE) okanye i-low pressure scraped surface heat exchanger (SSHE), okanye i-SSHE yoxinzelelo oluphezulu lwe-pasteurization ngaphambi kokungena kumgca we-crystallization.

Kwiimveliso ezityebileyo ezigcweleyo iPHE isetyenziswa ngokuqhelekileyo. Kwiinguqulelo ezisezantsi zamafutha apho i-emulsion ilindeleke ukuba ibonise i-viscosity ephezulu kunye ne-emulsions ehambelana nobushushu (umz. i-emulsions enomxholo ophezulu weprotheyini) inkqubo ye-SPX njengesisombululo soxinzelelo oluphantsi okanye i-SPX-PLUS njengesisombululo soxinzelelo oluphezulu luyacetyiswa.

Inkqubo ye-pasteurization ineenzuzo ezininzi. Iqinisekisa ukuvinjelwa kokukhula kwebhaktheriya kunye nokukhula kwamanye ama-micro-organisms, ngaloo ndlela kuphuculwe ukuzinza kwe-microbiological ye-emulsion. I-Pasteurization yesigaba samanzi kuphela yinto enokwenzeka, kodwa i-pasteurization ye-emulsion epheleleyo ikhethwa ukususela ekubeni inkqubo ye-pasteurization ye-emulsion iya kunciphisa ixesha lokuhlala ukusuka kwimveliso ye-pasteurized ukuzaliswa okanye ukupakishwa kwemveliso yokugqibela. Kwakhona, imveliso iphathwa kwinkqubo ye-in-line ukusuka kwi-pasteurization ukuzaliswa okanye ukupakishwa kwemveliso yokugqibela kunye ne-pasteurization yayo nayiphi na into eyenziwa ngokutsha iqinisekisiwe xa i-emulsion epheleleyo i-pasteurized.

Ukongezelela, i-pasteurization ye-emulsion epheleleyo iqinisekisa ukuba i-emulsion yondliwa kumgca we-crystallization kwiqondo lokushisa eliqhubekayo lifezekisa iiparitha zokucubungula rhoqo, ukushisa kwemveliso kunye nokuthungwa kwemveliso. Ukongezelela, isenzeko se-emulsion yangaphambi kwe-crystallized esondliwe kwisixhobo se-crystallization sithintelwa xa i-emulsion ifakwe ngokufanelekileyo kwaye yondliwe kwimpompo yoxinzelelo oluphezulu kwiqondo lokushisa kwe-5-10 ° C ngaphezu kwendawo yokunyibilika kwesigaba samafutha.

Inkqubo ye-pasteurization eqhelekileyo iya kuthi emva kokulungiswa kwe-emulsion kwi-45-55 ° C iquka ukufudumeza nokubamba ukulandelelana kwe-emulsion kwi-75-85 ° C kwi-16 sec. kwaye emva koko inkqubo yokupholisa ukuya kumaqondo obushushu angama-45-55°C. Iqondo lokushisa lokugqibela lixhomekeke kwinqanaba lokunyibilika kwesigaba samanqatha: ukuphakama kweqondo lokunyibilika, ukuphakama kweqondo lokushisa.

UKUPHILA, UKUKWETSHISWA OKUNYE NOKUGUQA (UZONINI 4)

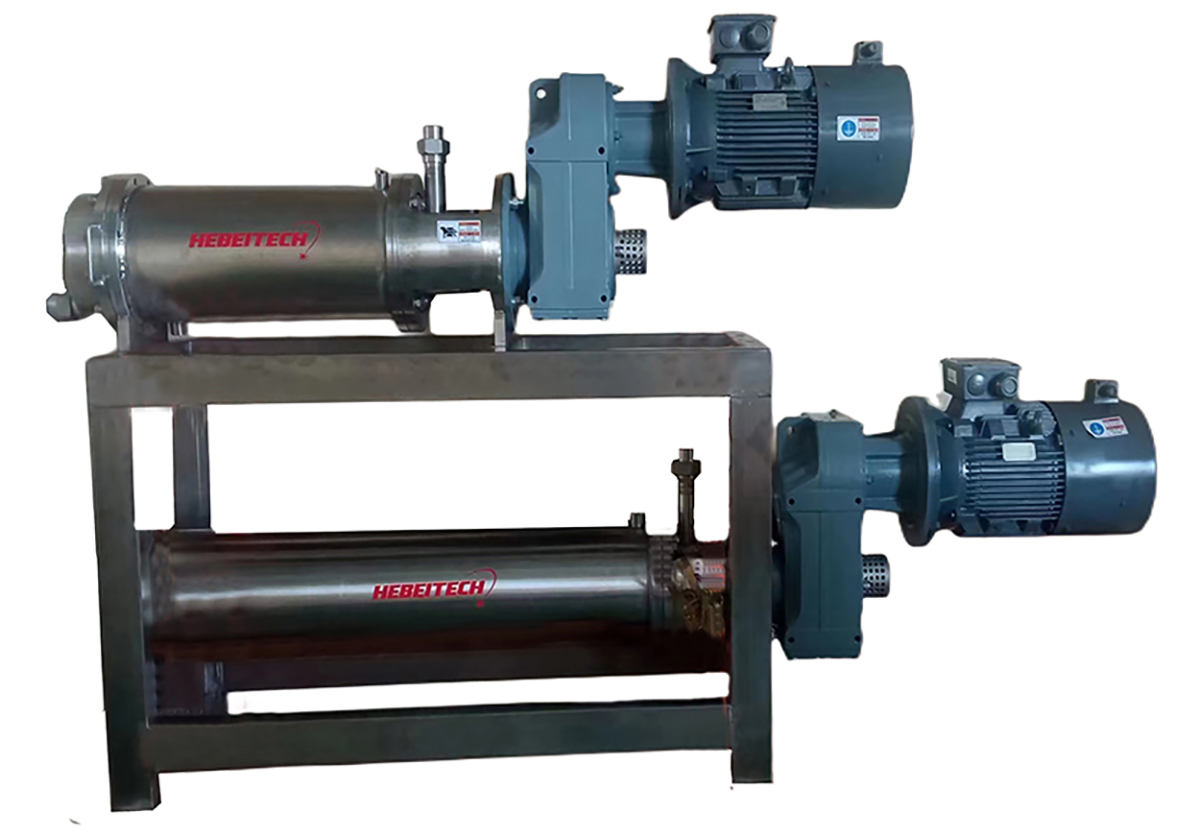

I-emulsion iphonswa kumgca we-crystallization ngokusebenzisa ipompo yepiston yoxinzelelo oluphezulu (HPP). Umgca we-crystallization wokuvelisa i-margarine kunye neemveliso ezihambelanayo ngokuqhelekileyo ziquka i-SSHE yoxinzelelo oluphezulu olupholileyo nge-ammonia okanye i-Freon uhlobo lweendaba zokupholisa. I-Pin rotor machine (s) kunye / okanye i-crystallizers ephakathi zihlala zibandakanyiwe kumgca ukwenzela ukongeza ubuninzi bokuxova kunye nexesha lokuveliswa kweemveliso zeplastiki. I-tube yokuphumla yinyathelo lokugqibela lomgca we-crystallization kwaye ifakwe kuphela ukuba imveliso ipakishwe.

Intliziyo yomgca we-crystallization yi-SSHE yoxinzelelo oluphezulu, apho i-emulsion efudumeleyo i-super-cooled kwaye i-crystallized kwi-internal surface ye-chilling tube. I-emulsion ikhutshwe ngokufanelekileyo yi-scrapers ejikelezayo, ngoko ke i-emulsion ipholile kwaye ixutywe ngaxeshanye. Xa amanqatha kwi-emulsion ecwebezelayo, iikristale zamanqatha zenza inethiwekhi enemigangatho emithathu ebambe amathontsi amanzi kunye neoyile elulwelo, okukhokelela kwiimveliso ezineempawu zeplastiki zendalo eziqinileyo.

Ngokuxhomekeke kuhlobo lwemveliso eza kuveliswa kunye nohlobo lwamafutha asetyenziselwa imveliso ethile, ukucwangciswa komgca we-crystallization (okt ukulandelelana kweetyhubhu ezibandayo kunye noomatshini be-pin rotor) kunokulungelelaniswa ukuze kubonelele ukucwangciswa okuphezulu kwemveliso ethile.

Ekubeni umgca we-crystallization uvame ukuvelisa ngaphezu kwemveliso enye yamanqatha, i-SSHE ihlala iquka amacandelo amabini okanye ngaphezulu okupholisa okanye iibhubhu zokupholisa ukwenzela ukuhlangabezana neemfuno zomgca we-crystallization flexible. Xa uvelisa iimveliso zamafutha adityanisiweyo ahlukeneyo adityaniswe ngamafutha, ubhetyebhetye luyafuneka kuba iimpawu zecrystallization zemixube zinokwahluka ukusuka kumxube omnye ukuya komnye.

Inkqubo ye-crystallization, iimeko zokucubungula kunye neeparitha zokucubungula zinempembelelo enkulu kwiimpawu zemargarine yokugqibela kunye nokusabalalisa iimveliso. Xa uyila umgca we-crystallization, kubalulekile ukuchonga iimpawu zeemveliso ezicetywayo ukuba zenziwe kumgca. Ukukhusela utyalo-mali lwexesha elizayo, ukuba bhetyebhetye komgca kunye neeparamitha ezilawulekayo ezilawulwa ngabanye ziyimfuneko, njengoko uluhlu lweemveliso ezinomdla zinokutshintsha ngokuhamba kwexesha kunye nemathiriyeli ekrwada.

Umthamo womgca unqunywe ngumgangatho wokupholisa okhoyo we-SSHE. Oomatshini bobungakanani obahlukeneyo bafumaneka ukusuka kwimigca esezantsi ukuya kwimizila ephezulu. Kwakhona idigri ezahlukeneyo zokuguquguquka ziyafumaneka ukusuka kwisixhobo setyhubhu enye ukuya kwimigca yetyhubhu emininzi, ngaloo ndlela imigca yokuqhuba ebhetyebhetye kakhulu.

Emva kokuba imveliso ipholile kwi-SSHE, ingena kumatshini we-pin rotor kunye / okanye i-crystallizers ephakathi apho ixutywe khona ixesha elithile kunye nobukhulu obuthile ukwenzela ukuncedisa ukunyuswa kwenethiwekhi ye-three-dimensional, leyo kwinqanaba le-macroscopic yisakhiwo seplastiki. Ukuba imveliso yenzelwe ukusasazwa njengemveliso esongiweyo, iya kungena kwakhona kwi-SSHE ngaphambi kokuba ihlale kwi-tube yokuphumla ngaphambi kokusonga. Ukuba imveliso izaliswe kwiikomityi, akukho ityhubhu yokuphumla ifakwe kumgca we-crystallization.

UKUPAKISHA, UKUZALISWA NOKUKHUMBULA ( UMZONE 5 )

Iintlobo ezahlukeneyo zokupakisha kunye nokuzalisa oomatshini ziyafumaneka kwiimarike kwaye aziyi kuchazwa kweli nqaku. Nangona kunjalo, ukuhambelana kwemveliso kuhluke kakhulu ukuba kuveliswe ukupakishwa okanye ukuzaliswa. Kucacile ukuba imveliso epakishiweyo kufuneka ibonise ukuthungwa okuqinileyo kunemveliso egcwalisiweyo kwaye ukuba oku kuguquguquka akulunganga imveliso iya kuphambukiswa kwisixokelelwano sokunyibilikiswa kwakhona, inyibilikiswe kwaye yongezwe kwitanki yesithinteli ukuze iphinde icocwe. Iinkqubo ezahlukeneyo zokunyibilikisa ziyafumaneka kodwa iinkqubo ezisetyenziswa kakhulu yiPHE okanye uxinzelelo oluphantsi lwe-SSHE.

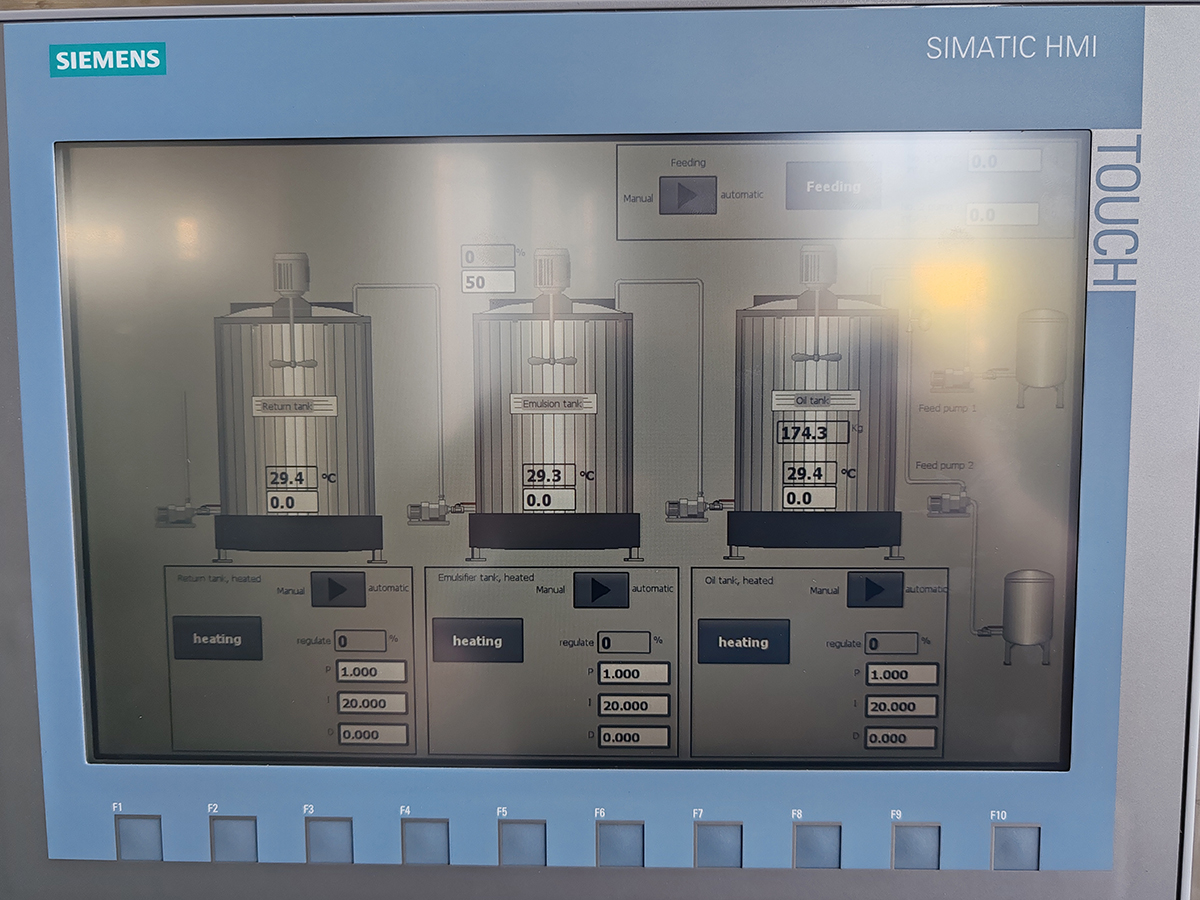

UZENZAKALO

Imargarine, njengezinye iimveliso zokutya, ikwiifektri ezininzi namhlanje ziveliswa phantsi kweenkqubo ezingqongqo zokulandela umkhondo. Ezi nkqubo zikholisa ukuquka izithako, imveliso kunye nemveliso yokugqibela ayipheleli ekukhuselekeni kokutya okuphuculweyo kodwa kumgangatho wokutya ongaguqukiyo. Iimfuno zokulandela umkhondo zingaphunyezwa kwinkqubo yokulawula yefektri kunye nenkqubo yokulawula ye-Shiputec yenzelwe ukulawula, ukurekhoda kunye nokubhala iimeko ezibalulekileyo kunye neeparitha malunga nenkqubo epheleleyo yokuvelisa.

Inkqubo yolawulo ixhotyiswe ngokukhuselwa kwegama eliyimfihlo kwaye ibonisa ukuloga kwedatha yembali yazo zonke iiparameters ezibandakanyekayo kumgca wokucubungula imajarini ukusuka kulwazi lweresiphi ukuya kuvavanyo lokugqibela lwemveliso. Ukungena kwedatha kubandakanya umthamo kunye nokukhutshwa kwempompo yoxinzelelo oluphezulu (l / iyure kunye noxinzelelo lwangasemva), ukushisa kwemveliso (kubandakanya inkqubo ye-pasteurization) ngexesha le-crystallization, ukushisa okupholileyo (okanye ukupholisa uxinzelelo lweendaba) ze-SSHE, isantya se-SSHE kunye noomatshini be-pin rotor kunye nomthwalo weemoto eziqhuba impompo yoxinzelelo oluphezulu, i-SSHE kunye nemishini ye-pin rotor.

Inkqubo yokulawula

Ngexesha lokucubungula, ii-alamu ziya kuthunyelwa kumqhubi ukuba iiparitha zokucubungula imveliso ethile zingaphandle kwemida; ezi zisetwe kumhleli weresiphi phambi kwemveliso. Ezi alarms kufuneka zivunywe ngesandla kwaye amanyathelo ngokwemigaqo kufuneka kuthathwe. Zonke ii-alam zigcinwa kwisistim ye-alam yembali ukuze ibonwe kamva. Xa imveliso ishiya umgca wemveliso kwifomu epakishwe ngokufanelekileyo okanye ezaliswe ngokupheleleyo, ingaphandle kwegama lemveliso eliphawulwe ngokuqhelekileyo ngomhla, ixesha kunye nenombolo yokuchongwa kwebhetshi yokulandelela kamva. Imbali epheleleyo yawo onke amanyathelo okuvelisa abandakanyekayo kwinkqubo yokuvelisa ifakwe ngoko ukhuseleko lomvelisi kunye nomsebenzisi wokugqibela, umthengi.

CIP

Izityalo zokucoca i-CIP (i-CIP = ukucocwa endaweni) nazo ziyinxalenye yesixhobo semajarini yanamhlanje ekubeni izityalo zokuvelisa imajarini kufuneka zicocwe rhoqo. Kwiimveliso zemajarini zemveli kanye ngeveki lixesha eliqhelekileyo lokucoca. Nangona kunjalo, kwiimveliso ezibuthathaka ezifana namafutha aphantsi (umthamo wamanzi aphezulu) kunye / okanye iprotheyini ephezulu equlethe iimveliso, ikhefu elifutshane phakathi kweCIP liyacetyiswa.

Ngokomgaqo, iinkqubo ezimbini ze-CIP zisetyenzisiweyo: izityalo ze-CIP ezisebenzisa imidiya yokucoca kanye kuphela okanye izityalo ze-CIP ezicetyiswayo ezisebenza ngesisombululo se-buffer seendaba zokucoca apho imidiya efana ne-lye, i-asidi kunye / okanye i-disinfectants ibuyiselwa kwiitanki zokugcina ze-CIP emva kokusetyenziswa. Inkqubo yokugqibela ikhethwa kuba imele isisombululo esilungele ukusingqongileyo kwaye iyisisombululo esinoqoqosho malunga nokusetyenziswa kwee-arhente zokucoca kwaye ke ngoko ixabiso lezi zinto.

Kwimeko apho imigca emininzi yokuvelisa ifakwe kwifektri enye, kunokwenzeka ukuseta iingoma zokucoca ezihambelanayo okanye iinkqubo zesathelayithi zeCIP. Oku kubangela ukunciphisa kakhulu ixesha lokucoca kunye nokusetyenziswa kwamandla. Iiparamitha zenkqubo ye-CIP zilawulwa ngokuzenzekelayo kwaye zifakwe kwi-trace emva kwexesha kwinkqubo yokulawula.

AMANQAKU OKUGQIBELA

Xa uvelisa imajarini kunye neemveliso ezinxulumeneyo, kubalulekile ukukhumbula ukuba ayizizo izithako kuphela ezifana namafutha kunye namafutha asetyenzisiweyo okanye iresiphi yemveliso emisela umgangatho wemveliso yokugqibela kodwa kunye nokucwangciswa kwesityalo, imilinganiselo yokucubungula kunye nemeko yesityalo. Ukuba umgca okanye izixhobo azigcinwanga kakuhle, kukho umngcipheko wokuba umgca awusebenzi ngokufanelekileyo. Ngoko ke, ukuvelisa iimveliso ezikumgangatho ophezulu, isityalo esisebenza kakuhle siyimfuneko kodwa ukhetho lokuxutywa kwamafutha kunye neempawu ezihambelana nokusetyenziswa kokugqibela kwemveliso nako kubalulekile kunye nokwakheka okuchanekileyo kunye nokukhetha imilinganiselo yokulungiswa kwesityalo. Okokugqibela kodwa imveliso yokugqibela kufuneka iphathwe ngeqondo lobushushu ngokusetyenziswa kokugqibela.

Ixesha lokuposa: Dec-19-2023