Umgca weMveliso yeSosi yeCustard

Umgca weMveliso yeSosi yeCustard

Umgca weMveliso yeSosi yeCustard

Ividiyo yeMveliso:https://www.youtube.com/watch?v=AkAcycJx0pI

Aumgca wemveliso yesosi yekhastadiibandakanya uthotho lweenkqubo ezizenzekelayo nezizenzekelayo ukwenza isosi ye-custard ngokufanelekileyo, ngokuqhubekayo, nangokucocekileyo. Apha ngezantsi kukho uhlalutyo oluneenkcukacha lwamanqanaba aqhelekileyo kumgca wokuvelisa isosi ye-custard:

1. Ukuphathwa kunye nokulungiswa kwezithako

- Ukwamkelwa nokugcinwa kobisi

- Ubisi olungavuthwanga luyafunyanwa, luvavanywe umgangatho, luze lugcinwe kwiindawo zokugcina ubisi ezifrijini.

- Enye indlela: Umgubo wobisi ohlaziyiweyo + amanzi (ukuze ugcinwe ixesha elide).

- Ukuphatha iswekile kunye neswekile

- Iswekile, isiraphu yombona, okanye ezinye izinto eziswiti ziyalinganiswa zize zinyibilikiswe.

- Ukucubungula umgubo wamaqanda kunye namaqanda

- Amaqanda angamanzi (afakwe ii-pasteurized) okanye umgubo wamaqanda axutywa namanzi.

- Isitatshi kunye neziQinisekisi

- Isitatshi sengqolowa, istatshi esiguquliweyo, okanye izithambisi (umz., i-carrageenan) zixutywa kwangaphambili ukuze kuthintelwe ukuqhekeka.

- Iincasa kunye nezongezo

- I-vanilla, i-caramel, okanye ezinye iincasa, kunye nezithinteli (ukuba ziyafuneka), ziyalungiswa.

2. Ukuxuba kunye nokudibanisa

- Ukuxubana Okuqhubekayo okanye Okubanzi

- Izithako zidityaniswe kwiumxube oxutywe kakhuluokanyeitanki yokuxuba kwangaphambiliphantsi kobushushu obulawulwayo (ukuthintela ukutyeba ngaphambi kwexesha).

- I-homogenization ingasetyenziswa ukuze kubekho ukuguda okuthambileyo.

3. Ukupheka kunye nokuPasteurization

- Ukupheka Okuqhubekayo (Isitshintshi Sobushushu Esikhuhliweyo)

- Umxube ushushu ukuze75–85°C (167–185°F)ukwenza i-starch gelatinization ibe nkulu kwaye ityebise isosi.

- Ukwenziwa kwePasteurization (i-HTST okanye iBatch)

- Ixesha elifutshane lobushushu obuphezulu (i-HTST) kwi72°C (161°F) imizuzwana eli-15-20okanye i-batch pasteurization ukuqinisekisa ukhuseleko lweentsholongwane.

- Isigaba sokuPholisa

- Ukupholisa ngokukhawuleza ukuya4–10°C (39–50°F)ukuyeka ukupheka ngakumbi nokugcina ubume bayo bucocekile.

4. Ukudibanisa (Ukhetho)

- I-Homogenizer yoxinzelelo oluphezulu

- Isetyenziselwa ukuguda okuthambileyo kakhulu (kuthintela ukuba neenkozo).

5. Ukuzalisa kunye nokuPakisha

- Oomatshini bokuzalisa abazenzekelayo

- Ukuzaliswa kwengxowa(ngeevenkile) okanyeukuzaliswa okukhulu(kwinkonzo yokutya).

- Ukuzaliswa kwe-Aseptic(ukuhlala ixesha elide) okanyeukugcwalisa okushushu(yokugcina izinto ezikufutshane).

- Iifomathi zokuPakisha:

- Iibhotile zeplastiki, iibhokisi, iingxowa, okanye iithini.

- Ukucoca nge-nitrogen kungasetyenziselwa ukwandisa ixesha lokugcinwa kwenkunkuma.

6. Ukupholisa kunye nokugcina

- Ukupholisa Ukuqhuma (ukuba kuyimfuneko)

- Kwikhastadi efrijini, ukupholisa ngokukhawuleza ukuya4°C (39°F).

- Indawo yokugcina izinto ezibandayo

- Igcinwe apha4°C (39°F)kwikhastadi entsha okanye kwindawo engqongileyo yeemveliso eziphathwe nge-UHT.

7. Ulawulo loMgangatho kunye noVavanyo

- Ukuhlolwa kobungqindilili(usebenzisa ii-viscometer).

- Ukubeka iliso kwi-pH(ithagethi: ~6.0–6.5).

- Uvavanyo lweMicrobiological(inani lilonke leepleyiti, imvubelo/isikhunta).

- Uvavanyo lweemvakalelo(incasa, ubunjani, umbala).

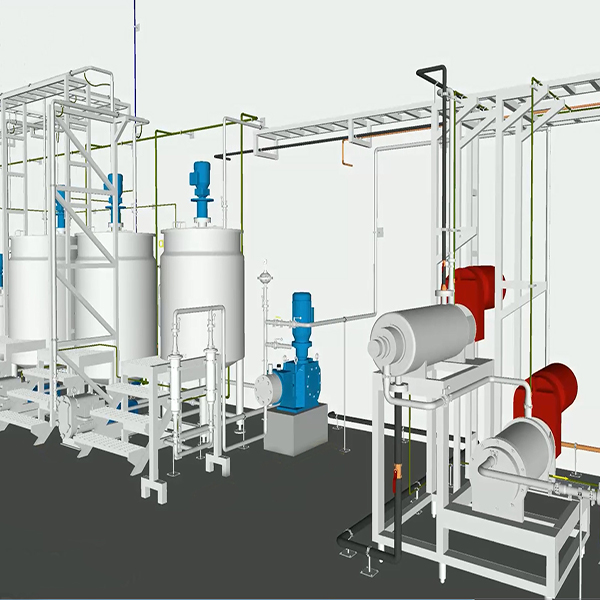

Izixhobo eziphambili kwiCustard Sauce Production Line

- Amatanki Okugcina Izinto(yobisi, izithako ezingamanzi).

- Iinkqubo zokuLinganisa kunye nokuDosa.

- IiTanki ze-High-Shear kunye ne-Premix Mixer.

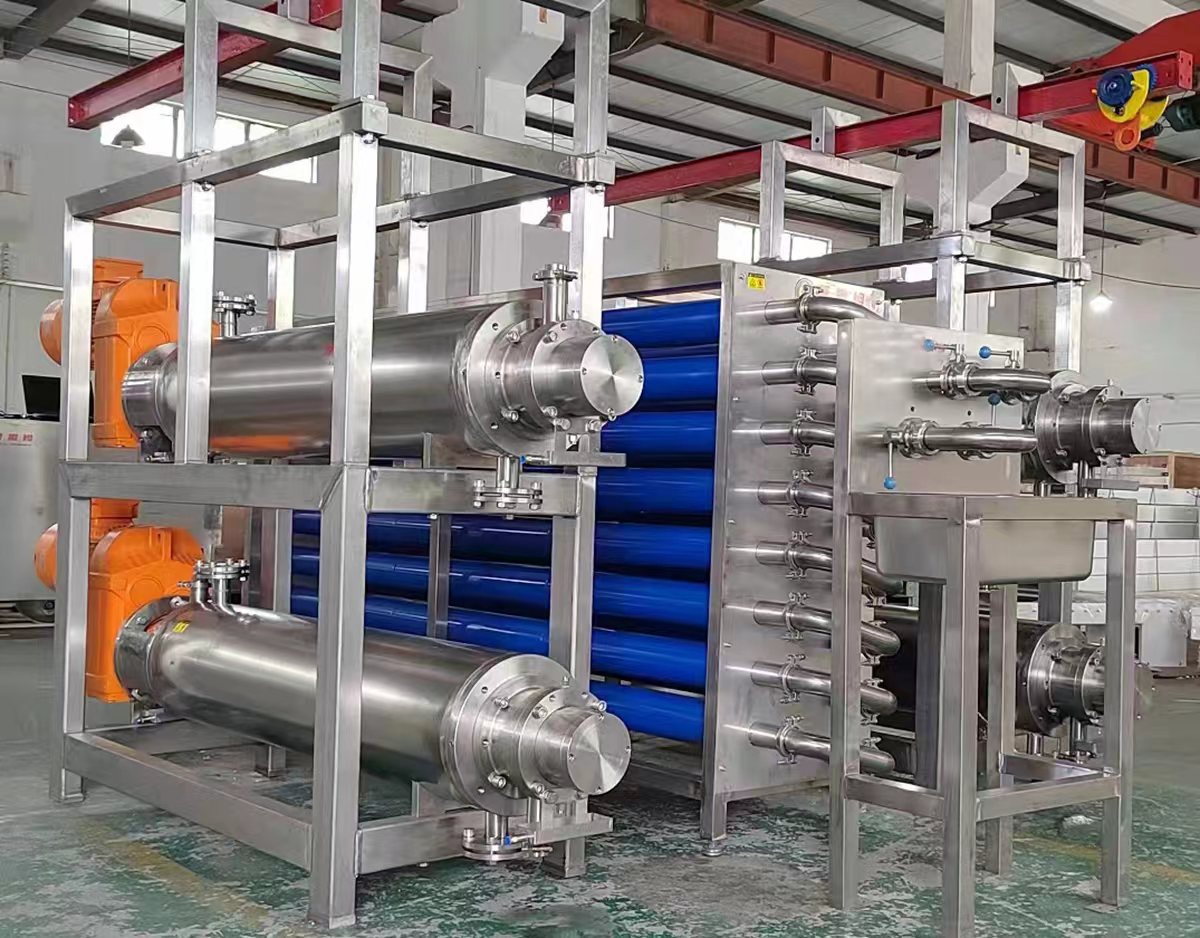

- I-Pasteurizer (i-HTST okanye iBatch).

- Isitshintshi sobushushu esikhutshiweyo (sokupheka).

- I-Homogenizer (ukhetho).

- Oomatshini bokugcwalisa (i-piston, i-volumetric, okanye i-aseptic).

- IiTunnels Zokupholisa.

- Oomatshini bokuPakisha (ukuvala, ukulebhelisha).

Iintlobo zeSosi yeCustard eziveliswayo

- Ikhastadi efrijini(ixesha elifutshane lokuhlala ixesha elide, incasa entsha).

- I-UHT Custard(ihlala ixesha elide eshelufini, ihlanjululwe iintsholongwane).

- Umxube weCustard oMgubo(yokwakhiwa ngokutsha).

Ukuzenzekelayo kunye nokusebenza kakuhle

- Iinkqubo zoLawulo lwe-PLCukuze kulawulwe ubushushu obuchanekileyo kunye nokuxuba.

- Iinkqubo zeCIP (zokucoca kwindawo)ngenxa yococeko.

Ukuqaliswa kweNdawo

Bhala umyalezo wakho apha uze uwuthumele kuthi